Contact Information

Address: B1, Zone 2, Jinyuan Industrial Park, West of Chaosheng Road, Jinping District, Shantou City

Phone:+86-0754-82483418

Email:2925754108@qq.com

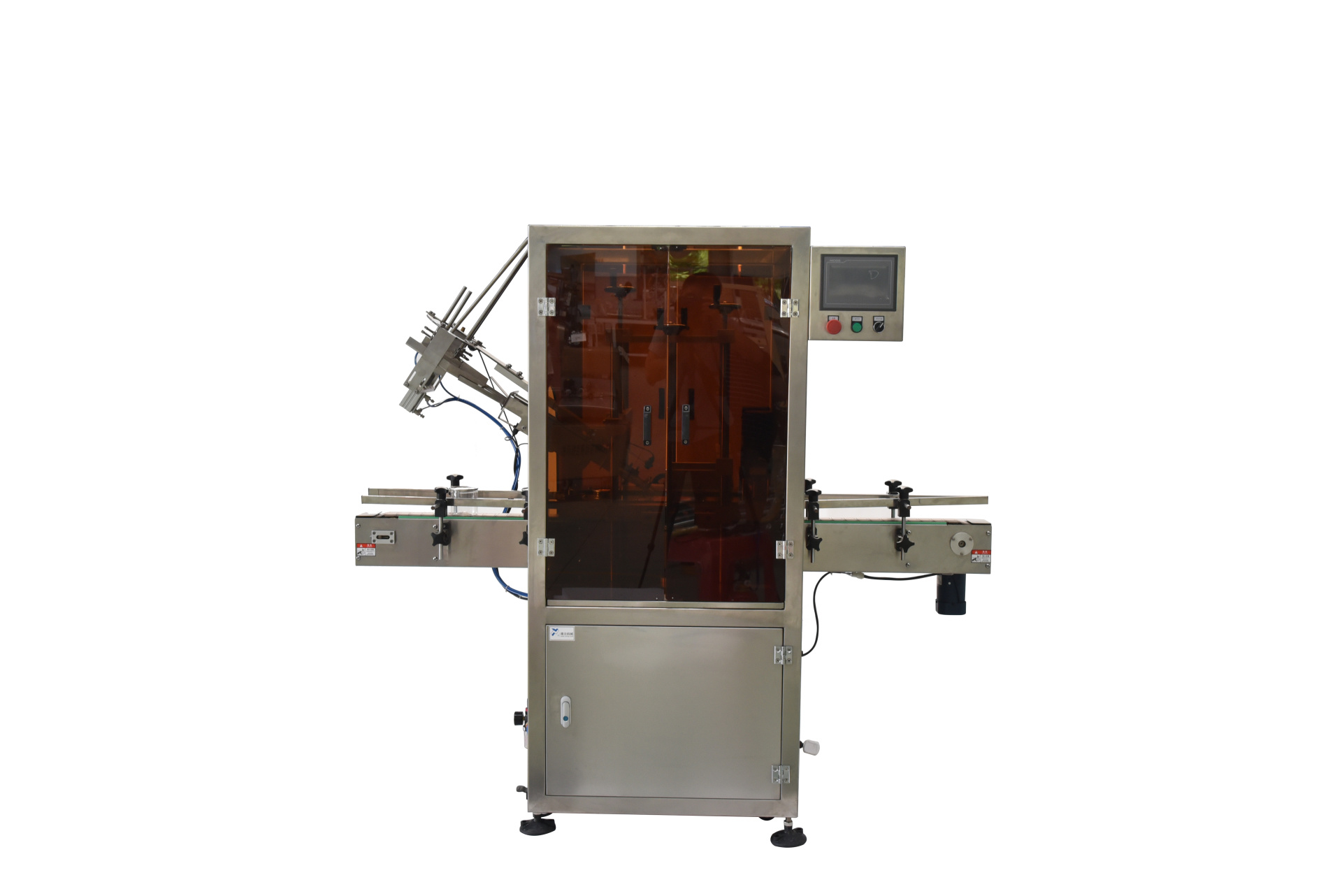

Bag-type vacuum packaging machine III

- Commodity name: Bag-type vacuum packaging machine III

- Product description

-

Main functions and features:

The rotary fully automatic bagging vacuum packaging machine consists of two separate rotary bodies (filling system and vacuum system respectively);

Easy operation: It adopts PLC touch screen control and a human-machine interface operating system, making operation intuitive and convenient;

Easy adjustment: It truly achieves full automation. Only input the required parameters from the human-machine interface, and the various parts of the packaging machine will automatically adjust to the required instruction;

High degree of automation: It achieves fully automatic vacuum requirements, realizing unmanned operation during weighing and packaging, with automatic fault alarm;

A complete preventive system can intelligently detect whether the bag is opened and whether the opening is complete. If the material is not suitable for adding, it will not add material or heat seal, avoiding waste of bags and materials, and saving costs;

The equipment meets the hygiene standards of food processing machinery. Parts of the equipment that come into contact with materials are made of 304 stainless steel or other materials that meet food hygiene requirements, ensuring food hygiene and safety, and complying with GMP standards;

It uses an oil-free vacuum pump to avoid polluting the production environment;

Easy to clean, the vacuum chamber is washable;

Pre-made packaging bags are used, with high sealing quality, and improving the grade of finished products.

Technical parameters:Equipment Name Bagging Vacuum Packaging Machine Ⅲ Equipment Model RZ8-200ZKⅢ Equipment Material 304 Stainless Steel Pneumatic Components SMC, AirTAC Vacuum Chamber Vacuum Pump Busch Drive Mode Variable frequency speed regulation motor drive Measurement Method Pickled vegetable metering machine, multi-head computer combination scale Operating Interface Touch screen (Chinese and English bilingual) Applicable packaging materials range Small fish fry, pickles, nuts and fried goods, spicy puffed food, chestnuts, liquids, etc. Packaging bag type Self-standing bags, handle bags, zipper bags, four-side sealed bags, three-side sealed bags, composite paper bags, etc. Packaging bag material Aluminum foil bags, composite flat bags, PE bags, PP bags Packaging bag specifications Width: 70~160mm Length: 80~200mm Workstation process Bagging → Coding + Opening → Feeding → Sequencing → Waste bag removal → Vacuuming + Heat sealing → Output Filling range 10~1500g Packaging speed 20~45 bags/min (speed depends on product characteristics and filling weight) Weighing accuracy Deviation ≤ ±1% Main unit weight 2000kg Main unit power 4.5kw Drive power supply 380V three-phase five-wire 50HZ Control power supply DC24V Compressed air consumption ≥0.2m3/min (compressed air is provided by the user) Optional supporting equipment Pickled vegetable metering machine, multi-head computer combination scale, work platform

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!