Contact Information

Address: B1, Zone 2, Jinyuan Industrial Park, West of Chaosheng Road, Jinping District, Shantou City

Phone:+86-0754-82483418

Email:2925754108@qq.com

Powder packaging line

- Commodity name: Powder packaging line

- Product description

-

Main Performance and Features:

Wide range of packaging: applicable to powders of various states and properties;

Applicable to different types of packaging bags;

Easy operation: PLC control, human-machine interface operating system, making operation intuitive and convenient;

Easy adjustment: variety change can be completed within about ten minutes;

High degree of automation: unmanned operation is realized throughout the weighing and packaging process, and automatic alarm is given in case of failure;

A complete prevention system can intelligently detect whether the bag is open and whether the opening is complete. It will not add material or heat seal if the material is not suitable to be added, avoiding waste of bags and materials, and saving costs;

The machine packaging parts are made of stainless steel material to ensure the hygiene and safety of materials, conforming to GMP standards;

Tolerance plastic bearings are used in some components, eliminating the need for oiling and reducing contamination of materials;

A vacuum generator is used, which is low-consumption, high-efficiency, clean, low-noise, and has a long service life;

Dust-proof and waterproof design, washable with water, reducing cleaning difficulty and improving machine service life;

Pre-made packaging bags are used, with high sealing quality, enhancing the grade of finished products;

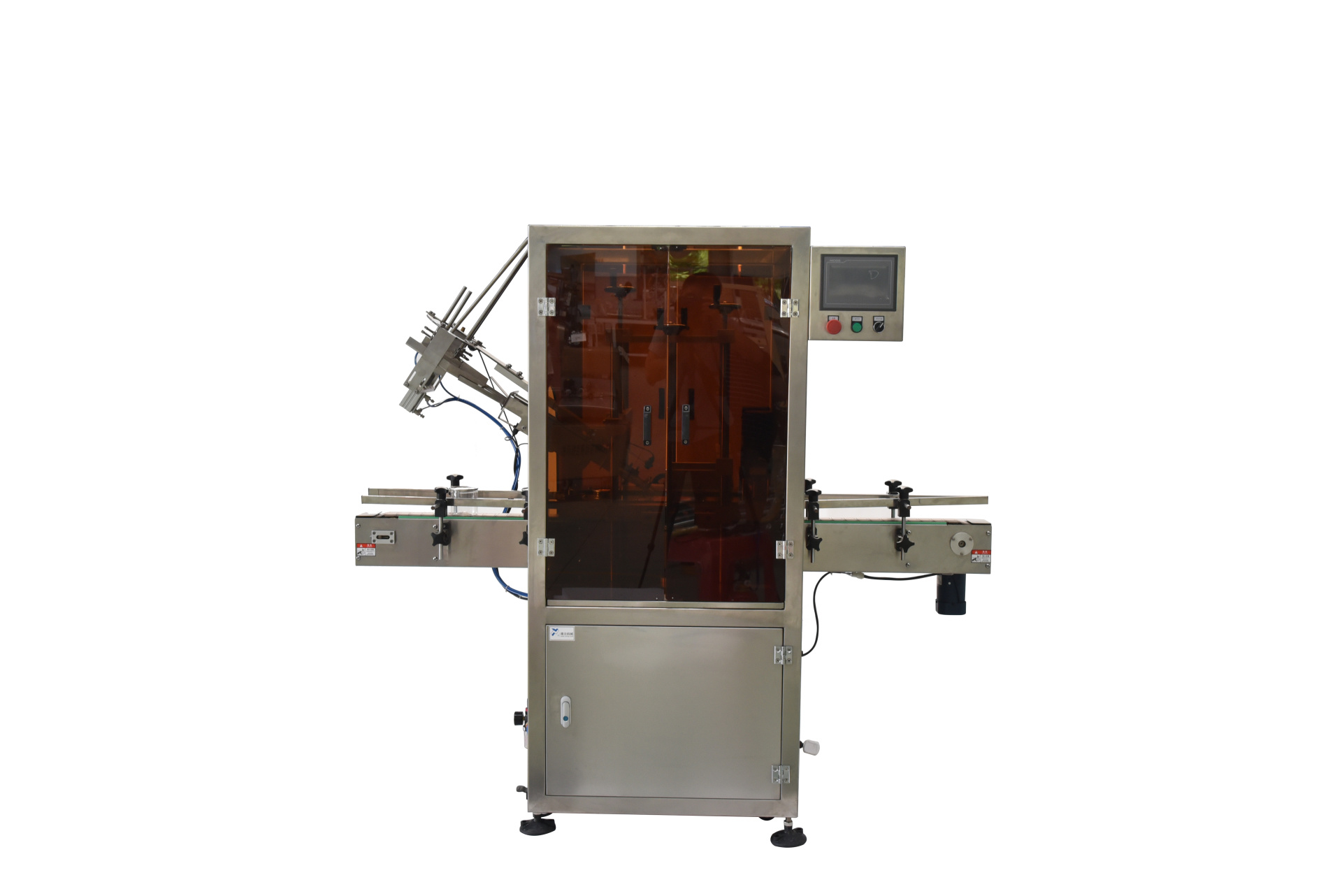

The equipment is equipped with a transparent plexiglass protective door.

Technical Parameters:

Equipment Name Automatic Powder Metering Packaging Production Line Equipment Model RZ8-300 Equipment Material 304 Stainless Steel Pneumatic Components SMC, AirTAC Vacuum Components Vacuum Pump (Holly Wang) Drive Mode Variable Frequency Speed Regulation Motor Drive Measurement Method Screw Weigher, Linear Weigher Operating Interface Touch screen (Chinese and English bilingual) Applicable Packaging Material Range Milk powder, coffee, seasonings, additives, etc. Packaging Bag Type Self-standing bag, handle bag, zipper bag, quad seal bag, three-side seal bag, paper bag, M-type bag, etc. Packaging Bag Material PA/PE, PET/PE, aluminum film, etc. Packaging Bag Specifications Width: 160~300mm Length: 100~400mm (Coding requires bag length over 140mm) Workstation Process 1. Bagging 2. Coding 3. Reserve 4. Opening 5. Feeding 6. Dust Removal 7. Heat Sealing 8. Shaping & Output Filling Range 5~2500g Packaging Speed 10~40 bags/min (Speed determined by product characteristics and filling quantity) Weighing Accuracy Deviation ≤ ±1% Main Unit Weight 2000kg Main Unit Dimensions 1645mm*1645mm*1640mm (Length, Width, Height) Main Unit Power 4kw Drive Power Supply 380V Three-phase Five-wire 50HZ Control Power Supply DC24V Compressed Air Consumption ≥0.35m3/min (Compressed air provided by the user) Optional Supporting Equipment Screw weigher, linear weigher, measuring cup, screw feeder, weight sorter, metal detector, vacuum cleaner

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!