Contact Information

Address: B1, Zone 2, Jinyuan Industrial Park, West of Chaosheng Road, Jinping District, Shantou City

Phone:+86-0754-82483418

Email:2925754108@qq.com

Fully automatic pickled vegetable packaging line

- Commodity name: Fully automatic pickled vegetable packaging line

- Product description

-

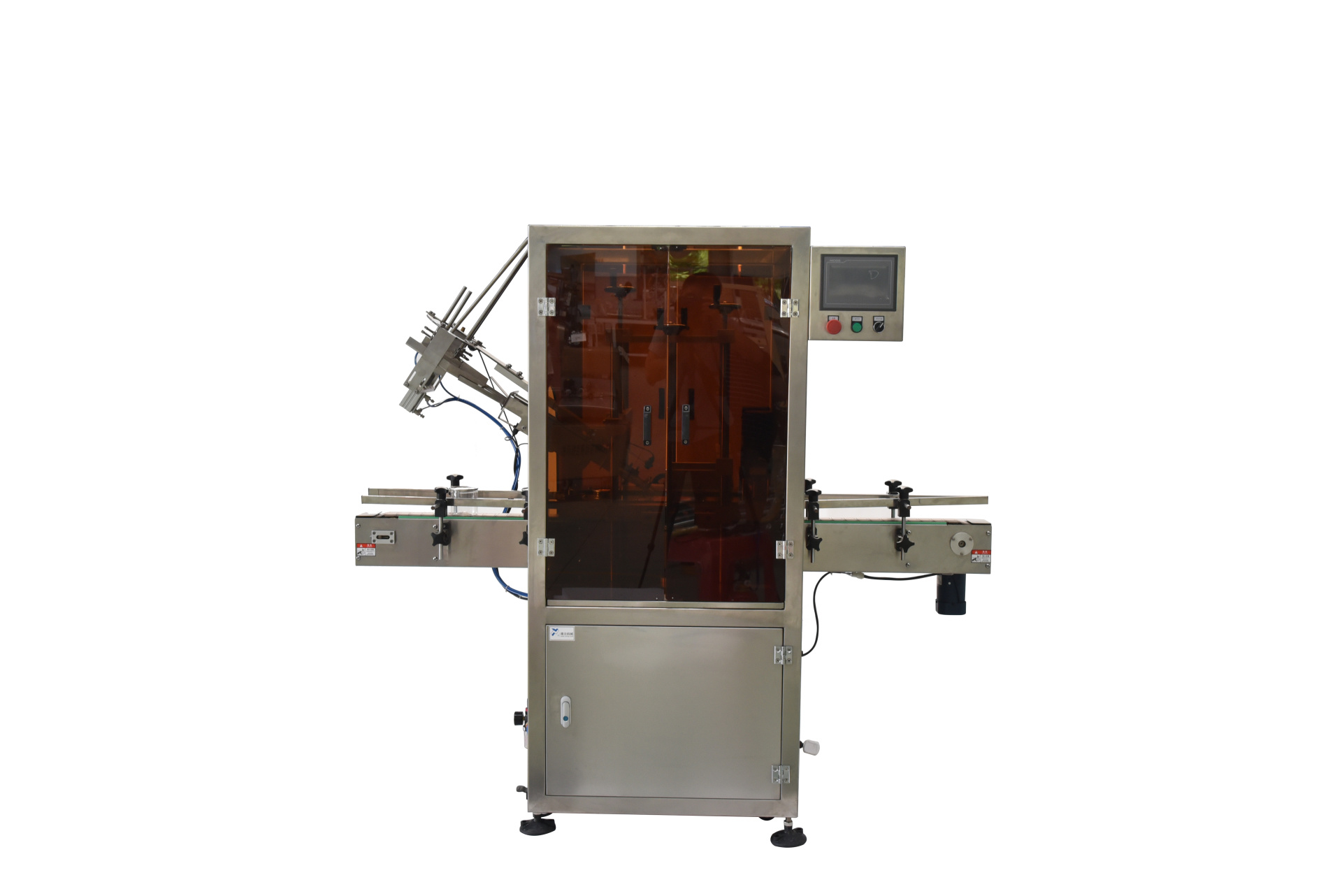

Equipment Name

Automatic Pickled Vegetable Weighing and Packaging Production Line

Equipment Model

RZ6-200JYC

Equipment Material

304 Stainless Steel

Pneumatic Components

SMC and AirTAC

Vacuum Components

Vacuum Generator (SMC)

Drive Type

Variable Frequency Speed Motor Drive

Measurement Method

Pickled Vegetable Metering Machine, Filling Machine

Operating Interface

Touch Screen (Chinese and English Bilingual)

Applicable Packaging Material Range

Pickled mustard tuber, preserved mustard greens, enoki mushrooms, dried radish, ginger slices and various pickled vegetables, jellyfish skin, fish sauce, etc.

Packaging Bag Type

Stand-up pouch, handle bag, zipper bag, quad seal bag, three-side seal bag, and other composite bags

Packaging Bag Material

PA/PE PET/PE, aluminum foil and other heat-sealing films

Packaging Bag Specifications

Width: 70~200mm Length: 100 ~220mm (coding requires bag length of 140mm or more)

Workstation Process

1. Bagging 2. Coding + Bag Opening 3. Material Dispensing 4. Liquid Addition 5. Heat Sealing 6. Output

Filling Range

5 ~500g

Packaging Speed

40 ~60 bags/ minute (speed depends on product characteristics and filling weight)

Weighing Accuracy

Deviation ≤±0.5-2g

Main Unit Weight

1000kg

Main Unit Dimensions

1 555mm*1405mm*2265mm (Length, Width, Height)

Main Unit Power

3kw

Drive Power Supply

380V Three-phase five-wire 50HZ

Control Power Supply

DC24V

Compressed Air Consumption

≥0.45m 3 /minute (compressed air to be provided by the user)

Optional Supporting Equipment

Single-bucket elevator, filling machine, pickled vegetable metering machine

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!