Contact Information

Address: B1, Zone 2, Jinyuan Industrial Park, West of Chaosheng Road, Jinping District, Shantou City

Phone:+86-0754-82483418

Email:2925754108@qq.com

Automatic metering and packaging production line for solids (granules)

- Commodity name: Automatic metering and packaging production line for solids (granules)

- Product description

-

Main performance and characteristics of the equipment:

Manufacturer: Ruizhi Machinery Co., Ltd.

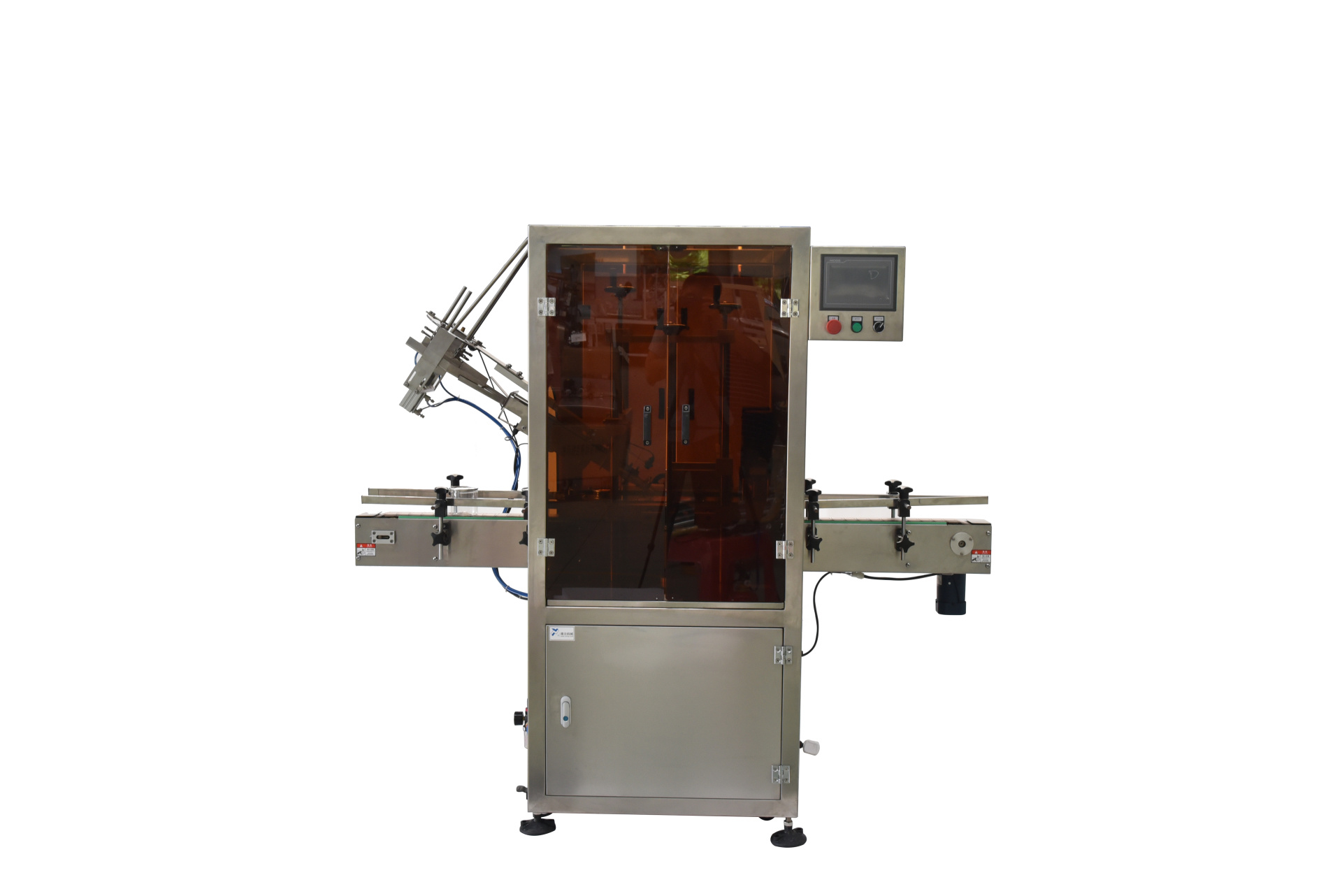

Equipment Name: Fully Automatic Rotary Bag Packaging Machine

Model: RZ8-200 (eight-station 200 type)

Wide range of packaging: Suitable for various shapes, states, and properties of particles and blocky materials;

Suitable for different types of packaging bags;

Easy operation: PLC control, human-machine interface operating system, making operation intuitive and convenient;

Easy adjustment: Changeover time is approximately within ten minutes;

High degree of automation: Unmanned operation is achieved throughout the weighing and packaging process, with automatic alarm in case of malfunctions;

Complete preventive system, can intelligently detect whether the bag is open and whether the opening is complete. It will not add materials or heat-seal if the conditions are not suitable, avoiding waste of bags and materials, thus saving costs;

The packaging parts of the machine are made of stainless steel to ensure the hygiene and safety of the materials, complying with GMP standards;

Some components use tolerance plastic bearings, eliminating the need for oiling and reducing contamination of materials;

Uses an oil-free vacuum pump to avoid polluting the production environment;

Uses pre-made packaging bags, with high sealing quality and enhanced product appearance;

The equipment is equipped with a transparent plexiglass protective door.

Equipment Technical Parameters

Equipment Name

Solid (Granular) Packaging Machine

Model

RZ8-200

Material

304 Stainless Steel

Pneumatic Components

SMC, AirTAC

Vacuum Components

Vacuum Generator (SMC)

Drive Type

Variable Frequency Speed Motor Drive

Measurement Method

Multi-Head Combination Electronic Scale

Operating Interface

Touch Screen (Bilingual: Chinese and English)

Applicable Packaging Material Range

Candies, nuts, raisins, peanuts, melon seeds, kernels, potato chips, chocolates, biscuits, and other large particles and irregularly

shaped blocksPackaging Bag Type

Stand-up pouches, handle bags, zipper bags, quad-seal bags, three-side seal bags, paper bags, M-shaped bags, and other composite bags

Packaging Bag Material

PA/PE, PET/PE, aluminum foil, and other heat-sealable films

Packaging Bag Specifications

Width: 70~200mm Length: 100~300mm (coding requires bag length over 140mm)

Workstation Process

1. Bagging 2. Coding 3. Bag Opening 4. Material Discharge 5. Material Pushing 6. Reserved 7. Heat Sealing 8. Shaping & Output

Filling Range

5~1500g

Packaging Speed

20~55 bags/min (speed depends on product characteristics and filling weight)

Weighing Accuracy

Deviation ≤ ±1%

Main Unit Weight

800kg

Main Unit Dimensions

1475mm*1325mm*1480mm (Length, Width, Height)

Main Unit Power

1.5kw

Drive Power Supply

380V Three-phase Five-wire 50HZ

Control Power Supply

DC24V

Compressed Air Consumption

≥0.45m3/min (compressed air to be provided by the user)

Optional Supporting Equipment

Multi-head computer combination weigher, linear weigher, Z-type elevator, high-angle elevator, single-bucket elevator, weight sorter, metal detector, work platform

Keywords:

Online Inquiry

Note: Please leave your email address, our professionals will contact you as soon as possible!